Home – Sherpa

About Us

Most Reliable 3D Printing Services, All the Time

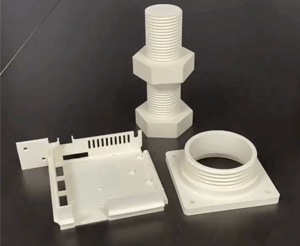

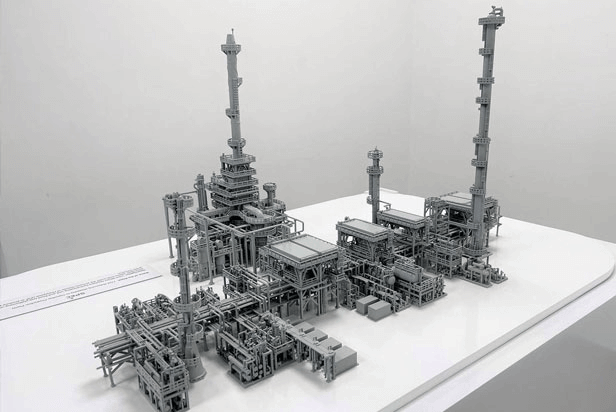

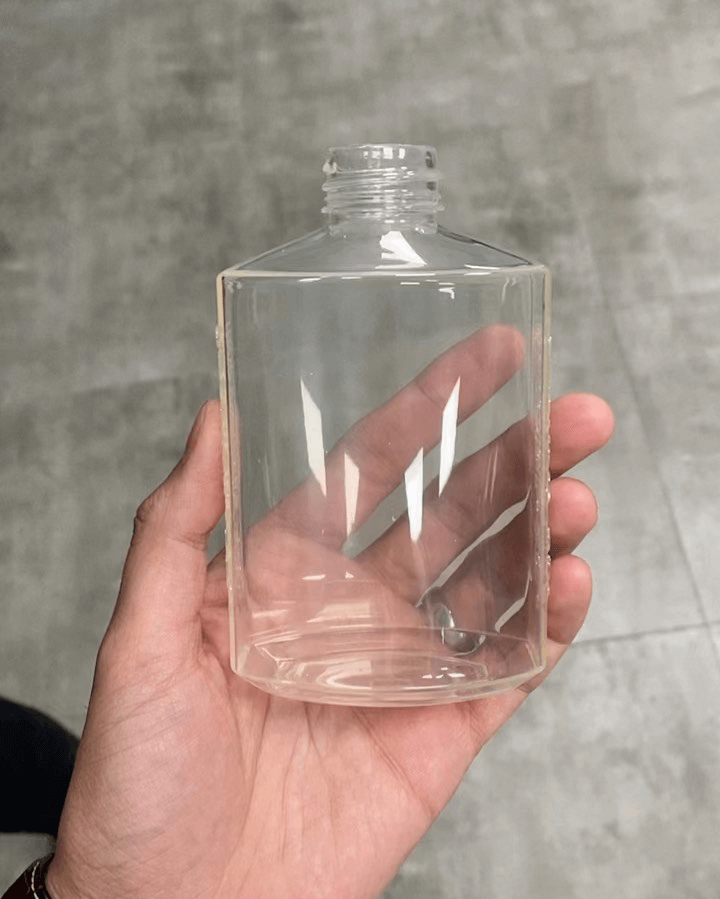

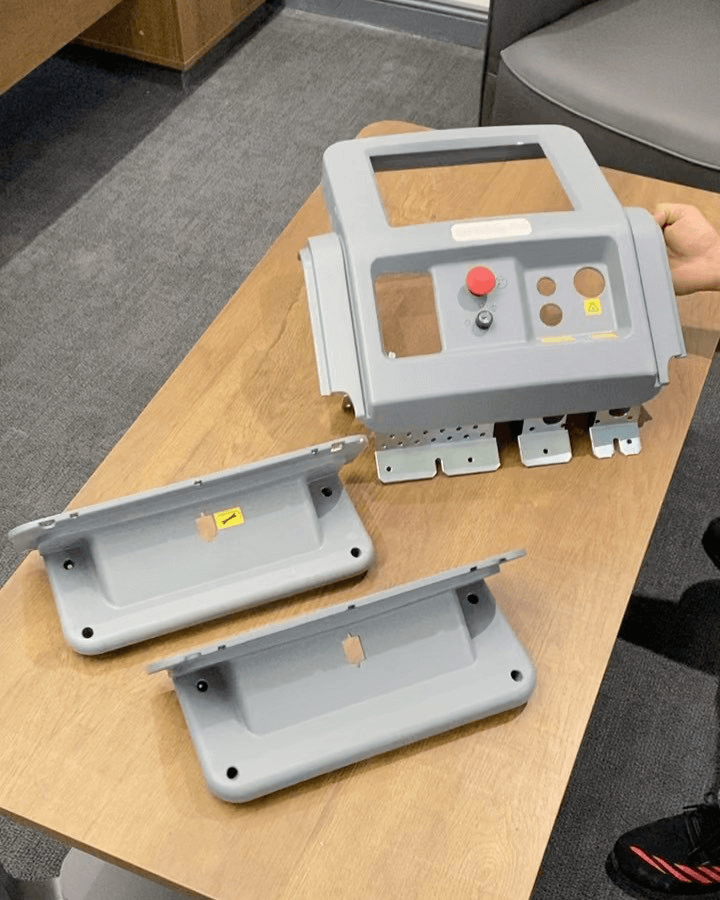

Proto21 is the fastest-growing 3D printing services provider in the UAE. We cater to a wide range of industries with affordable and accessible manufacturing and prototyping solutions, and we’re committed to delivering top-notch and high-end quality manufacturing services.

Our Services

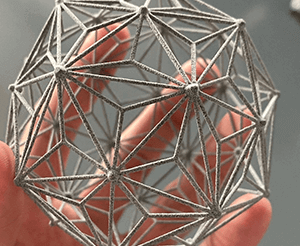

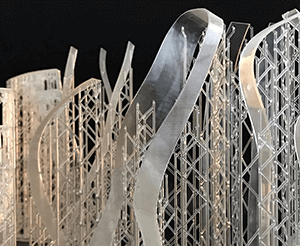

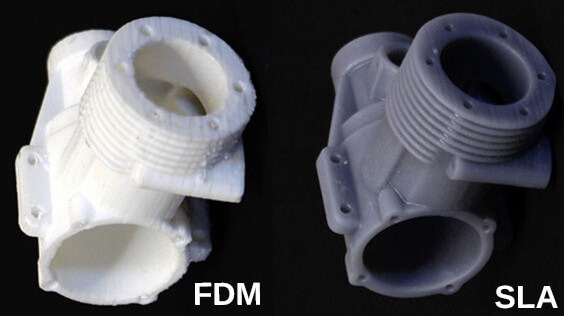

Exceptional-Quality 3D Printing in the UAE

Materials

3D Manufacturing Materials

23+

Countries Served

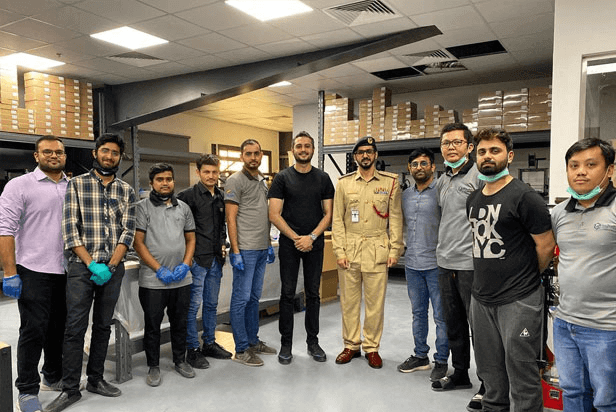

30+

Team Members

60+

3D Printers

15.9K+

Parts printed per Month

Our Clients

Trusted by Market Leaders

Technologies

Your Local Manufacturing Partner

Testimonials

We Are A Company You Can Trust

News & Media